Retro-Fit? Retro-Clad?----We Supply All the

Anchors & Misc Metals for These Jobs Too!

| MEMBER: |  |

LET US MAKE THESE PARTS FOR YOU TOO

Many new projects are actually re-builds of sound older buildings that need to be brought up to current standards for one or more of myriad reasons. No metal fabricator has more expertise and more focused experience than Metfab Metals, LLC on such jobs. A good example is the full replacement of the exterior skin (or envelope) of the United Nations Building in NYC which we did a few years back.

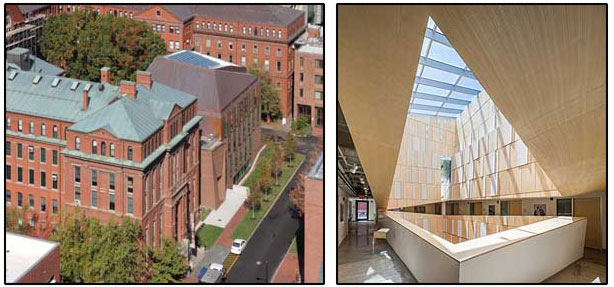

[“51 Louisiana”: Another Metfab Metals retro job ("roof ladder" covering) we did years ago in Washington, DC]

[“51 Louisiana”: Another Metfab Metals retro job ("roof ladder" covering) we did years ago in Washington, DC]

But what does this “retro-fit” actually mean? Well, a “retro-fit” or “retro-clad” job can take many forms, all defined by the specs issued for the project. Most simply, it can just mean furnishing new parts or equipment not available at the time of original construction. Or it can be a more full-blown tear-out where the building is stripped down to its super-structure and every system, covering, cladding and finish is replaced, often to adapt it to a new use or purpose. Regularly today, the purpose can be expressed in one word: GREEN, that is, the owners want to make the building far more energy efficient with power & maintenance savings offsetting much of the retro-fit costs. We are currently doing a major such job at Alexander Court in Virginia. This is a common project today, especially to gain better energy efficiency, gain more internal (expanded) space, adapt to a new use, re-purpose the entire building---and more. Such was the case recently with the century-old Tozzer Library at Harvard. Look what this archaic building turned into---and read the brief excerpt below as to such “building envelopes”.

|

The importance of campus building envelopes is more than skin deep. That fact is becoming increasingly evident when it is time for repairs and renovations. Indeed, elements such as façades, windows, and roofs can importantly aid efforts to improve building performance. Such efforts can be integrated. Upgrades to a building’s mechanical systems, for example, need to be accompanied by a close look at the building envelope because the latter can greatly impact the former. Craig Schwitter and Erik Verboon of Buro Happold, an engineering consulting firm, put it this way: “We are no longer in an age where we can pump energy into a building without the right envelope.” (1) |

As we here at Metfab Metals know our industry (& yours) and always focus on how we can better handle your job’s needs, this means we can---and do---supply ALL the metal products you need for such a ”retro” project. Currently, we are supplying various aspects of the fabricated metals for the Alexander Court re-styling of that preserved building in Alexandria, VA.

As this process of planning and spec’ing regularly starts BEFORE we are offered a PO for the final fabricated metal needed at the jobsite, (2) we ask our regular customers to involve us more in this planning stage. This is a NO-cost offer in which we take a look at what metals are needed and give the Owner & Design Team a chance to take advantage of our hands-on, current experience as to what works best in our aspect of the plans (yet to be finalized). Last month, here in this space, we talked about the value of VMU’s and PMU’s and how we offer that service. This is an item that can be considered a wise investment on many retro jobs. (3)

We often take an order for a VMU or PMU (4) at an early pre-construction stage so the design team can see exactly they want, perhaps see how it reacts to the elements and issue revised specs, drawings and PO’s along those adjusted lines. In our long experience, a VMU is an ultimately cost-effective way to qualitatively test whether your specs have a problem well-worth solving before committing to building out all the fabricated steel your design calls for, as well as ancillary parts such as glass, color, fillers, nuts & bolts and much more.

1. Building Design & Construction (online magazine) at www.bcdnetwork.com (September 16, 2009) by Mark Baker, Pres., IBA Consultants

2. Look again at how we have accommodated customers---and triggered cost-savings and error-avoidance with this modality.

3. PMU is the acronym for Performance MockUp. Basically the distinction between “Visual” and “Performance” models is that in the former it is made just so the owner, contractor(s) and Design Team can visually inspect it to better judge how it will “look” in its final, erected form, whereas the PMU is made to be shipped to retained experts to “perform” a series of tests to see how the model reacts to the stresses and strains of later actual use. See generally Building Design & Construction (online magazine) at www.bcdnetwork.com

4. College Planning & Management, Scott Berman, June 1, 2013.

Metfab Metals has decades of experience producing all the various metal parts/assemblies needed for YOUR retro jobs that can serve to make them go smoothly from its earliest stages------------and end successfully! Call us; you’ll soon see we produce.

Call me for ALL your METALS questions. If I can't answer it, I have all the needed "sources" to do so!

Jim Murray, C.O.O. 973-675-7676