Metfab Metals, LLC

| MEMBER: |  |

"IT’S ALL ABOUT THE VIEW"

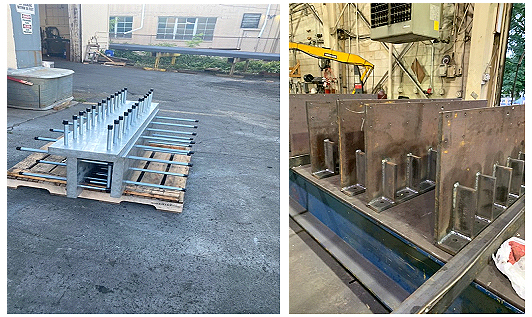

(Metfab Shop Photos of our fabricated “SHOE” elements)

(Metfab Shop Photos of our fabricated “SHOE” elements)

To better explain our headline above, Metfab Metals must add that, in turn, this “view” is made possible only because of this “shoe” (see pictures below). And that “shoe” is one we make, but no one ever walks in. It’s a GLASS SHOE! It’s the kind of “shoe” that makes upper floors’ safety the priority while also accommodating the most unobstructed view that the engineer can approve or the architect can design. [For an awe-inspiring analogy, look below at the “shelf” of glass floor that extends out over the precipitous gorge of the USA’s Grand Canyon that allows us to almost “walk on air” out into the same Grand Canyon and gaze thousands of feet down into its mouth through the actual floor you’re standing on.] The counterpart of the “foot” that goes into this shoe is a precision set of pre-engineered glass sheets (in lieu of a non-transparent steel or solid medium, with some sheets as large as 12’ X 20’) that allows people to view all that surrounds them. Our shoes assemble into a continuous deep-set “track” which, rising solely from the floor grade, hold securely in place that set of these glass panels that, in turn, assemble into a transparent “fence” or rail that surround balconies, staircases and the like (thus projecting the desired “view”).

[YES, the "floor" these folks are standing on is totally transparent GLASS. Courtesy of Wikipedia]

An example of our current “shoe-making” is the project for which we are making the specialty fabrications (unique “shoes”) illustrated in our brief shop pictures above. We have implemented a template to make all the sections required for an 80th floor view on a new building rising in NYC as you read this now in 2020. These fabrications, once assembled and secured with the unbreakable glass manufactured just for this unique application, will allow all present to view the panorama of Manhattan, almost as if they were passengers on a drone above the street. Corners will be mitered together or precise butt joints put in place and secured as necessary to finish.

Metfab Metals works for all our customers, large & small as well as for many medium-sized businesses, on projects of all scopes, but a current job in Manhattan (NYC, not Kansas) has hefted our resume’ for making these essential “glass shoes” that make feasible high-rise viewing platforms, surrounds and restraints, often hundreds or even thousands of feet above the bustling streets below.

[An example of a glass “fence”secured in a “shoe”, courtesy of CR Laurence]

[An example of a glass “fence”secured in a “shoe”, courtesy of CR Laurence]

And everything we fabricate or sell is made right here in the USA---America, unlike the above railing from Canada.

But our message today is---We here at Metfab Metals are ready and have already “hit the ground running”, making these kinds of specialty fabrications here in the USA! Our experienced staff is back in our shops and our office staff is working both remotely and here in the office per what we learned as “best practices” during the height of the “virus shutdown”. Prior to this Pandemic shutdown, we already had decades of experience in such special processes as AESS, but we were fast accumulating real expertise in “shoe-making” also. Call us, come in and see all we can do on your jobs.

Take advantage of all our great services and quality fabrications that we can provide now, better than ever! So, Faithful Customers, SEND IT IN! We will turn around your orders faster than ever! And always accurately and as drawn.

Metfab Metals has done such futuristic & cutting edge jobs featuring all manner of challenging fabrications, as the AESS and shoes outlined above.. Our owner, Jim Murray, has many times remarked how our purchase orders seemingly always reflect current trends in New York and beyond. We can (even in this time of mobilizing to get past this Coronavirus crisis) electronically receive your drawings and RFQ; return a full quotation sooner than any competitor; act promptly on your PO; obtain shop drawings; meet your fabrication challenges; promptly make your parts and assemblies; fulfill all your QC & LEED documentation requirements;& otherwise provide anything your specs call for.

Metfab Metals can again rightly say that we have decades of experience and skills in all manner of truly

specialty fabrications (and all the needed technology to support these) so that we can help YOUR

jobs go smoothly from its earliest stages------------and end successfully!

Call us; you’ll soon see we produce.

Call me for ALL your METALS questions. If I can't answer it,

I have all the needed "sources" to do so!

Jim Murray, C.O.O. 973-675-7676

We always offer to work with our customers from the job concept stage to anticipate issues before

fabrication, to suggest better ways to order, extrude, cut, drill, paint, finish, even stage

and deliver and always to save time and money