Metfab Metals, LLC

Boston’s Newest Show-Piece 21st Century Project is in Our Shop Now

| MEMBER: |  |

While we do a good deal of our jobs (especially for regular customers or on an emergency basis) in the tri-state area, one such regular customer (Island Properties of NY) has commissioned us to supply the specialty steel they need for a Boston job of significant public dimension. Look at these pictures of partially finished project here:

[These are just two angles to view the storefront we fabricated, as installed]

Metfab Metals has supplied many, many high-profile public projects outside our immediate region before, largely because of our specialty skills, experience and deserved reputation of always delivering on time and on spec. The National Museum of African America History & Culture in Washington, DC (the most recent Smithsonian Museum) a few years back is perhaps the best example. (Go to our website for a great deal of information and background on this extensive, successful work we did there. metfabmetals.com/projects) The current Hudson Yards multiplex is also reported there as another example of the scope of our skills.

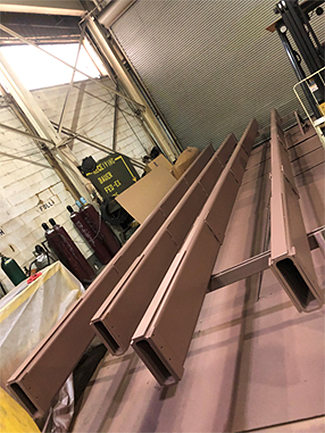

We here at Metfab Metals are presently working with our customer [Island Properties of Long Island, NY] to supply other specialty metals for this project. Pictured below are mullion reinforcement parts fabricated and finished as specified. We are also working on built-up boxed beams, among other items to be supplied.

[Finished mullion reinforcements]

Remember us for all your specialty metals work. What high-end work we are doing here at Metfab Metals for this innovative project as well as for LGA (the new Delta Terminal at LaGuardia Airport1 , just outside Manhattan) we can also do for your challenging projects also. Try us, you’ll see. We want to be your “GO TO” guys on all your challenging jobs also, as we are for so many long-term customers. We are expert fabricators not just of precision soffits as at LGA, but also for AESS, Glass Shoes, Assemblies and many specialty fabrications and finishes; we always bring to this kind of specialty work decades of experience that effectively solves problems before we ship to your jobsites. Let us bring to your varied projects the same care, quality control and effort from the getgo that we build into precision specialty parts every day.

1. Look at our Newsletter just last month for more detail on this unique job.

Keep us in mind for all your steel fabrication jobs, no matter the configuration

of the building, its scope, content, sophistication, or specifications.

Jim Murray, C.O.O. 973-675-7676

We always offer to work with our customers from the

job "concept" stage to anticipate issues before fabrication, to suggest

better ways to order, extrude, cut, drill, paint, finish, even stage and

deliver and always to save time and money.